During the heating cycle, heat is taken from outdoor air and “pumped” indoors.

- First, the liquid refrigerant passes through the expansion device, changing to a low-pressure liquid/vapour mixture. It then goes to the outdoor coil, which acts as the evaporator coil. The liquid refrigerant absorbs heat from the outdoor air and boils, becoming a low-temperature vapour.

- This vapour passes through the reversing valve to the accumulator, which collects any remaining liquid before the vapour enters the compressor. The vapour is then compressed, reducing its volume and causing it to heat up.

- Finally, the reversing valve sends the gas, which is now hot, to the indoor coil, which is the condenser. The heat from the hot gas is transferred to the indoor air, causing the refrigerant to condense into a liquid. This liquid returns to the expansion device and the cycle is repeated. The indoor coil is located in the ductwork, close to the furnace.

The ability of the heat pump to transfer heat from the outside air to the house depends on the outdoor temperature. As this temperature drops, the ability of the heat pump to absorb heat also drops. For many air-source heat pump installations, this means that there is a temperature (called the thermal balance point) when the heat pump’s heating capacity is equal to the heat loss of the house. Below this outdoor ambient temperature, the heat pump can supply only part of the heat required to keep the living space comfortable, and supplementary heat is required.

It is important to note that the vast majority of air-source heat pumps have a minimum operating temperature, below which they are unable to operate. For newer models, this can range from between -15°C to -25°C. Below this temperature, a supplemental system must be used to provide heating to the building.

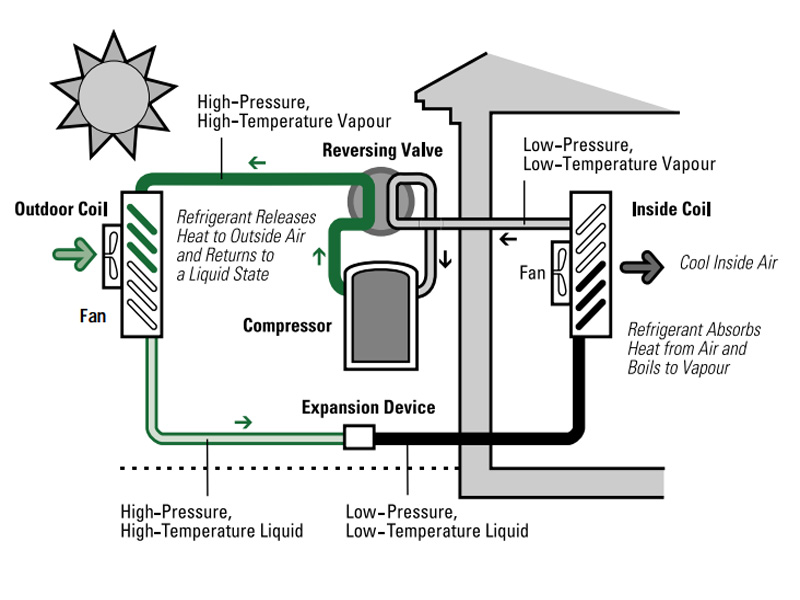

The Cooling Cycle

The cycle described above is reversed to cool the house during the summer. The unit takes heat out of the indoor air and rejects it outside.

- As in the heating cycle, the liquid refrigerant passes through the expansion device, changing to a low-pressure liquid/vapour mixture. It then goes to the indoor coil, which acts as the evaporator. The liquid refrigerant absorbs heat from the indoor air and boils, becoming a low-temperature vapour.

- This vapour passes through the reversing valve to the accumulator, which collects any remaining liquid, and then to the compressor. The vapour is then compressed, reducing its volume and causing it to heat up.

- Finally, the gas, which is now hot, passes through the reversing valve to the outdoor coil, which acts as the condenser. The heat from the hot gas is transferred to the outdoor air, causing the refrigerant to condense into a liquid. This liquid returns to the expansion device, and the cycle is repeated.

During the cooling cycle, the heat pump also dehumidifies the indoor air. Moisture in the air passing over the indoor coil condenses on the coil’s surface and is collected in a pan at the bottom of the coil. A condensate drain connects this pan to the house drain.

The Defrost Cycle

If the outdoor temperature falls to near or below freezing when the heat pump is operating in the heating mode, moisture in the air passing over the outside coil will condense and freeze on it. The amount of frost buildup depends on the outdoor temperature and the amount of moisture in the air.

This frost buildup decreases the efficiency of the coil by reducing its ability to transfer heat to the refrigerant. At some point, the frost must be removed. To do this, the heat pump switches into defrost mode. The most common approach is:

- First, the reversing valve switches the device to the cooling mode. This sends hot gas to the outdoor coil to melt the frost. At the same time the outdoor fan, which normally blows cold air over the coil, is shut off in order to reduce the amount of heat needed to melt the frost.

- While this is happening, the heat pump is cooling the air in the ductwork. The heating system would normally warm this air as it is distributed throughout the house.

One of two methods is used to determine when the unit goes into defrost mode:

- Demand-frost controls monitor airflow, refrigerant pressure, air or coil temperature and pressure differential across the outdoor coil to detect frost accumulation.

- Time-temperature defrost is started and ended by a pre-set interval timer or a temperature sensor located on the outside coil. The cycle can be initiated every 30, 60 or 90 minutes, depending on the climate and the design of the system.

Unnecessary defrost cycles reduce the seasonal performance of the heat pump. As a result, the demand-frost method is generally more efficient since it starts the defrost cycle only when it is required.

Supplementary Heat Sources

Since air-source heat pumps have a minimum outdoor operating temperature (between -15°C to -25°C) and reduced heating capacity at very cold temperatures, it is important to consider a supplemental heating source for air-source heat pump operations. Supplementary heating may also be required when the heat pump is defrosting. Different options are available:

- All Electric: In this configuration, heat pump operations are supplemented with electric resistance elements located in the ductwork or with electric baseboards. These resistance elements are less efficient than the heat pump, but their ability to provide heating is independent of outdoor temperature.

- Hybrid System: In a hybrid system, the air-source heat pump uses a supplemental system such as a furnace or boiler. This option can be used in new installations, and is also a good option where a heat pump is added to an existing system, for example, when a heat pump is installed as a replacement for a central air-conditioner.

See the final section of this booklet, Related Equipment, for more information on systems that use supplementary heating sources. There, you can find discussion of options for how to program your system to transition between heat pump use and supplementary heat source use.

Energy Efficiency Considerations

To support understanding of this section, refer to the earlier section called An introduction to Heat Pump Efficiency for an explanation of what HSPFs and SEERs represent.

In Canada, energy efficiency regulations prescribe a minimum seasonal efficiency in heating and cooling that must be achieved for the product to be sold in the Canadian market. In addition to these regulations, your province or territory may have more stringent requirements.

Minimum performance for Canada as a whole, and typical ranges for market-available products, are summarized below for heating and cooling. It is important to also check to see whether any additional regulations are in place in your region before selecting your system.

Cooling Seasonal Performance, SEER:

- Minimum SEER (Canada): 14

- Range, SEER in Market Available Products: 14 to 42

Heating Seasonal Performance, HSPF

- Minimum HSPF (Canada): 7.1 (for Region V)

- Range, HSPF in Market Available Products: 7.1 to 13.2 (for Region V)

Note: HSPF factors are provided for AHRI Climate Zone V, which has a similar climate to Ottawa. Actual seasonal efficiencies may vary depending on your region. A new performance standard that aims to better represent performance of these systems in Canadian regions is currently under development.

The actual SEER or HSPF values depend on a variety of factors primarily related to heat pump design. Current performance has evolved significantly over the last 15 years, driven by new developments in compressor technology, heat exchanger design, and improved refrigerant flow and control.

Single Speed and Variable Speed Heat Pumps

Of particular importance when considering efficiency is the role of new compressor designs in improving seasonal performance. Typically, units operating at the minimum prescribed SEER and HSPF are characterized by single speed heat pumps. Variable speed air-source heat pumps are now available that are designed to vary the capacity of the system to more closely match the heating/cooling demand of the house at a given moment. This helps to maintain peak efficiency at all times, including during milder conditions when there is lower-demand on the system.

More recently, air-source heat pumps that are better adapted to operating in the cold Canadian climate have been introduced to the market. These systems, often called cold climate heat pumps, combine variable capacity compressors with improved heat exchanger designs and controls to maximize heating capacity at colder air temperatures, while maintaining high efficiencies during milder conditions. These types of systems typically have higher SEER and HSPF values, with some systems reaching SEERs up to 42, and HSPFs approaching 13.

Certification, Standards, and Rating Scales

The Canadian Standards Association (CSA) currently verifies all heat pumps for electrical safety. A performance standard specifies tests and test conditions at which heat pump heating and cooling capacities and efficiency are determined. The performance testing standards for air-source heat pumps are CSA C656, which (as of 2014) has been harmonised with ANSI/AHRI 210/240-2008, Performance Rating of Unitary Air-Conditioning & Air-Source Heat Pump Equipment. It also replaces CAN/CSA-C273.3-M91, Performance Standard for Split-System Central Air-Conditioners and Heat Pumps.

Sizing Considerations

To appropriately size your heat pump system, it is important to understand the heating and cooling needs for your home. It is recommended that a heating and cooling professional be retained to undertake the required calculations. Heating and cooling loads should be determined by using a recognized sizing method such as CSA F280-12, “Determining the Required Capacity of Residential Space Heating and Cooling Appliances.”

The sizing of your heat pump system should be done according to your climate, heating and cooling building loads, and the objectives of your installation (e.g., maximizing heating energy savings vs. displacing an existing system during certain periods of the year). To help with this process, NRCan has developed an Air-Source Heat Pump Sizing and Selection Guide. This guide, along with a companion software tool, is intended for energy advisors and mechanical designers, and is freely available to provide guidance on appropriate sizing.

If a heat pump is undersized, you will notice that the supplemental heating system will be used more frequently. While an undersized system will still operate efficiently, you may not get the anticipated energy savings due to a high use of a supplemental heating system.

Likewise, if a heat pump is oversized, the desired energy savings may not be realized due to inefficient operation during milder conditions. While the supplemental heating system operates less frequently, under warmer ambient conditions, the heat pump produces too much heat and the unit cycles on and off leading to discomfort, wear on the heat pump, and stand-by electric power draw. It is therefore important to have a good understanding of your heating load and what the heat pump operating characteristics are to achieve optimal energy savings.

Other Selection Criteria

Apart from sizing, several additional performance factors should be considered:

- HSPF: Select a unit with as high an HSPF as practical. For units with comparable HSPF ratings, check their steady-state ratings at –8.3°C, the low temperature rating. The unit with the higher value will be the most efficient one in most regions of Canada.

- Defrost: Select a unit with demand-defrost control. This minimizes defrost cycles, which reduces supplementary and heat pump energy use.

- Sound Rating: Sound is measured in units called decibels (dB). The lower the value, the lower the sound power emitted by the outdoor unit. The higher the decibel level, the louder the noise. Most heat pumps have a sound rating of 76 dB or lower.

Installation Considerations

Air-source heat pumps should be installed by a qualified contractor. Consult a local heating and cooling professional to size, install, and maintain your equipment to ensure efficient and reliable operations. If you are looking to implement a heat pump to replace or supplement your central furnace, you should be aware that heat pumps generally operate at higher airflows than furnace systems. Depending on the size of your new heat pump, some modifications may be needed to your ductwork to avoid added noise and fan energy use. Your contractor will be able to give you guidance on your specific case.

The cost of installing an air-source heat pump depends on the type of system, your design objectives, and any existing heating equipment and ductwork in your home. In some cases, additional modifications to the ductwork or electrical services may be required to support your new heat pump installation.

Operation Considerations

You should note several important things when operating your heat pump:

- Optimize Heat Pump and Supplemental System Set-points. If you have an electric supplemental system (e.g., baseboards or resistance elements in duct), be sure to use a lower temperature set-point for your supplemental system. This will help to maximize the amount of heating the heat pump provides to your home, lowering your energy use and utility bills. A set-point of 2°C to 3°C below the heat pump heating temperature set-point is recommended. Consult your installation contractor on the optimal set-point for your system.

- Set Up for an Efficient Defrost. You can reduce energy use by having your system set up to turn off the indoor fan during defrost cycles. This can be performed by your installer. However, it is important to note that defrost may take a little longer with this set up.

- Minimize Temperature Setbacks. Heat pumps have a slower response than furnace systems, so they have more difficultly responding to deep temperature setbacks. Moderated setbacks of not more than 2°C should be employed or a “smart” thermostat that switches the system on early, in anticipation of a recovery from setback, should be used. Again, consult your installation contractor on the optimal setback temperature for your system.

- Optimize Your Airflow Direction. If you have a wall mounted indoor unit, consider adjusting the airflow direction to maximize your comfort. Most manufacturers recommend directing airflow downwards when heating, and towards occupants when in cooling.

- Optimize fan settings. Also, be sure to adjust fan settings to maximize comfort. To maximize the heat delivered of the heat pump, it is recommended to set the fan speed to high or ‘Auto’. Under cooling, to also improve dehumidification, the ‘low’ fan speed is recommended.

Maintenance Considerations

Proper maintenance is critical to ensure your heat pump operates efficiently, reliably, and has a long service life. You should have a qualified contractor do annual maintenance on your unit to ensure everything is in good working order.

Aside from annual maintenance, there are a few simple things you can do to ensure reliable and efficient operations. Be sure to change or clean your air filter every 3 months, as clogged filters will decrease airflow and reduce the efficiency of your system. Also, be sure that vents and air registers in your home are not blocked by furniture or carpeting, as inadequate airflow to or from your unit can shorten equipment lifespans and reduce efficiency of the system.

Operating Costs

The energy savings from installing a heat pump can help to reduce your monthly energy bills. Achieving a reduction in your energy bills greatly depends on the price of electricity in relation to other fuels such as natural gas or heating oil, and, in retrofit applications, what type of system is being replaced.

Heat pumps in general come at a higher cost compared to other systems such as furnaces or electric baseboards due the number of components in the system. In some regions and cases, this added cost can be recouped in a relatively short time period through the utility cost savings. However, in other regions, varying utility rates can extend this period. It is important to work with your contractor or energy advisor to get an estimate of the economics of heat pumps in your area, and the potential savings you can achieve.

Life Expectancy and Warranties

Air-source heat pumps have a service life of between 15 and 20 years. The compressor is the critical component of the system.

Most heat pumps are covered by a one-year warranty on parts and labour, and an additional five- to ten-year warranty on the compressor (for parts only). However, warranties vary between manufacturers, so check the fine print.

Remark:

Some of the articles are taken from the Internet. If there is any infringement, please contact us to delete it. If you’re interesting in heat pump products,please feel free to contact OSB heat pump company,we are your best choice.

Post time: Nov-01-2022