Vertical

Large commercial buildings and schools often use vertical systems because the land area required for horizontal loops would be prohibitive. Vertical loops are also used where the soil is too shallow for trenching, and they minimize the disturbance to existing landscaping. For a vertical system, holes (approximately four inches in diameter) are drilled about 20 feet apart and 100 to 400 feet deep. Two pipes, connected at the bottom with a U-bend to form a loop, are inserted into the hole and grouted to improve performance. The vertical loops are connected with horizontal pipe (i.e., manifold), placed in trenches, and connected to the heat pump in the building.

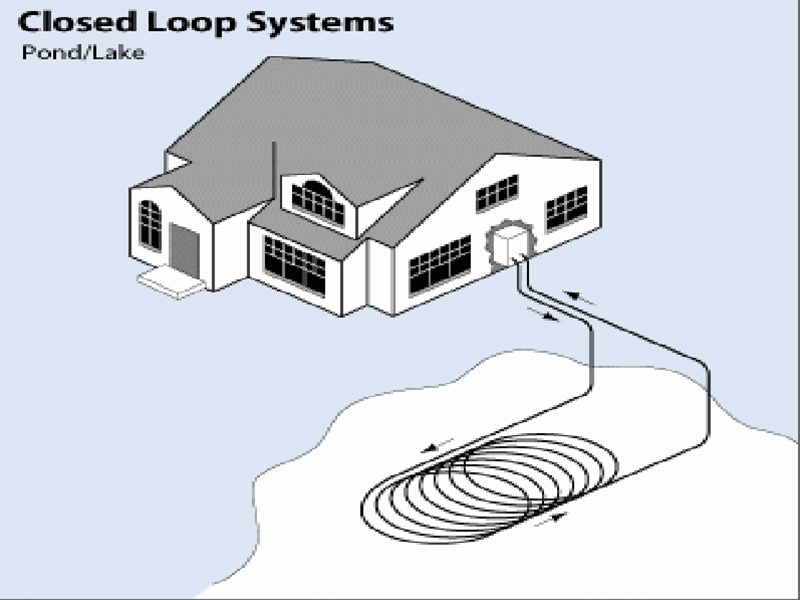

Pond/Lake

If the site has an adequate body of water, this may be the lowest cost option. A supply line pipe is run underground from the building to the water and coiled into circles at least eight feet under the surface to prevent freezing. The coils should only be placed in a water source that meets minimum volume, depth, and quality requirements.

Open-Loop System

This type of system uses well or surface body water as the heat exchange fluid that circulates directly through the GHP system. Once it has circulated through the system, the water returns to the ground through the well, a recharge well, or surface discharge. This option is obviously practical only where there is an adequate supply of relatively clean water, and all local codes and regulations regarding groundwater discharge are met.

Hybrid Systems

Hybrid systems using several different geothermal resources, or a combination of a geothermal resource with outdoor air (i.e., a cooling tower), are another technology option. Hybrid approaches are particularly effective where cooling needs are significantly larger than heating needs. Where local geology permits, the “standing column well” is another option. In this variation of an open-loop system, one or more deep vertical wells is drilled. Water is drawn from the bottom of a standing column and returned to the top. During periods of peak heating and cooling, the system can bleed a portion of the return water rather than reinjecting it all, causing water inflow to the column from the surrounding aquifer. The bleed cycle cools the column during heat rejection, heats it during heat extraction, and reduces the required bore depth.

Remark:

Some of the articles are taken from the Internet. If there is any infringement, please contact us to delete it. If you're interesting inground source heat pump products,please feel free to contact OSB heat pump company,Ine are your best choice.

Post time: Apr-03-2023